- ABOUT

- ENVIRONMENT

-

PRODUCTS

- Heating industry

- Water conservancy industry

- Coal mine gas industry

- Coal coking industry

- Coal washing and mineral processing industry

- Chemical industry

- Petroleum and petrochemical industry

- Natural gas industry

- Electric power application industry

- Urban construction industry

- Water supply and drainage fire protection industry

- Steel smelting industry

- Food and pharmaceutical industry

- Environmental Application industry

- NEWS

- APPLICATION

- SERVICE

- CONTACT US

- YD343HA Gas butterfly valve

- Z41H gate valve

- HH44H Check Valve

- MA electric actuator

- MA control box

- Q11F stainless steel ball valve

- Z941H electric gate valve

- Q341F manual ball valve

- Y42X Pressure relief valve

- Water distribution gate valve

- Globe valve

- Check valve

- Ball valve

- Quick mounted high pressure ball valve

- Ultra high pressure groove gate valve

YD343HA Gas butterfly valve

YD343HAGas butterfly valve has the characteristics of simple structure, small volume, light weight, low material consumption, small installation size, quick switch, 90 ° reciprocating rotation, small driving torque, etc. it is used to cut off, connect and adjust the medium in the pipeline, and has good fluid control characteristics and sealing performance. It can transport mud and store the least liquid at the pipe mouth. Under low pressure, it can achieve good sealing and good regulation performance. The streamline design of the butterfly plate of the explosion-proof electric butterfly valve greatly reduces the fluid resistance, which can be described as an energy-saving product. The valve rod of the electric butterfly valve is of through-bar structure. After quenching and tempering, it has good mechanical properties, corrosion resistance and scratch resistance. When the explosion-proof electric gas butterfly valve is opened and closed, the valve rod only rotates and does not move up and down. The packing of the valve rod is not easy to be damaged and the sealing is reliable. The butterfly plate taper pin is fixed, and the extended end is designed to prevent the valve rod from collapsing when the connection between the valve rod and the butterfly plate breaks accidentally.

1, because the sealing pair and packing of the butterfly valve are mostly made of polytetrafluoroethylene, counterpoint polystyrene, nylon, rubber and other high polymer, it is easy to generate static electricity in the process of frequent opening and closing, used in part of the flammable and explosive medium occasions will hit sparks, causing hidden dangers.

Special gas valve with anti - static structure is required.

The butterfly valve manufactured by our factory is equipped with missile spring between butterfly plate, valve stem and valve body, which will pass the static electricity into the pipeline in time and lead it into the ground to ensure the safety of the system.

2, butterfly valve is an indispensable key component in pipeline transportation, in order to prevent the fire, due to the damage of the sealing surface caused by the loss of a large number of media, butterfly valve is designed to be fire-resistant structure, that is, after the soft material melted to form a metal hard seal, during the fire to prevent the outflow of some media cause greater losses.According to the needs of users, butterfly valve seat and stem of the sealing part, can be equipped with grease valve, when the sealing part due to wear or other reasons leakage, through the grease valve injection sealing grease, temporary sealing role, in order to take effective rescue measures in time.

3, butterfly valve can be designed as an extension of the operating mechanism according to the needs, suitable for the pipeline buried auxiliary installation site.Butterfly valves are designed for low temperature conditions with a long neck to keep packing away from the medium and avoid packing failure.There are essential differences between this structure and the lengthening of the operating mechanism.

4, high temperature resistance, wear resistance, long service life.Butterfly valve is the biggest difference: the use of three eccentric design structure.The butterfly plate installation center and rotation center are designed with rigorous eccentricity: when the valve opens 10° or even fully open, the butterfly valve seat sealing surface and butterfly plate are in a non-contact state, butterfly plate with the stem rotation and deflect into the valve seat sealing surface to make it sealed.Therefore, due to the opening and closing process of less, no wear and tear to extend the service life of the valve.

5, when the butterfly valve pipeline fluid pressure into the seat sealing slot, due to Posson's force acting principle, the sealing element in the pipeline pressure and O-ring expansion force generated by the resultant force, seat sealing surface squeezed to butterfly plate and valve sealing.This unique sealing structure can produce more sealing force with the increase of pipeline pressure.

6. The seat of this butterfly valve can be fine-tuned.In the valve after a certain number of years, when the sealing ring wear leakage, in the case of not opening the valve, by adjusting screw to the direction of the sealing ring butterfly plate fine adjustment to the required size, can be compensated and have the same sealing performance of the new valve.

7. The multi-layer hard sealed dazzle valve series can be equipped with manual devices, pneumatic devices or electric devices to form manual butterfly valve, pneumatic butterfly valve (with feedback signals and electric-gas valve positor) and electric butterfly valve and other three categories of six series products.

8. Our butterfly valve is not only simple in structure, small in size, light in weight, less in material consumption, small in installation size, small in driving torque, simple and fast in operation, but also can have a good flow control joint function and close sealing characteristics at the same time. It is one of the fastest valve varieties developed in recent decades.Our metal sealed butterfly valves are high temperature, high pressure, high sealing, long life, excellent regulation characteristics and one valve multi-purpose function, its reliability and other performance indicators are up to a higher level.The original butterfly valve is a simple baffle valve with lax closing.It is usually used in water pipeline system as flow control valve and mud resistance valve.The performance of butterfly valves is improved by the use of chemically resistant synthetic rubber.Because the synthetic rubber has corrosion resistance, erosion resistance, size stability, good resilience, easy to shape, low cost and other characteristics, and can be used according to different requirements to choose different properties of synthetic rubber, to meet the working conditions of butterfly valve, so it is widely used in the manufacturing of butterfly valve lining and elastic seat.In order to meet the requirements of high and low temperature, corrosion resistance, long service life and other industrial applications, in the last decade, our metal seal butterfly valve has been developed greatly.With high temperature resistant, good low temperature resistance, strong corrosion resistance, strong erosion resistance, high strength alloy materials in the application of screw valve, make the metal sealing waltz valve in high and low temperature, strong erosion, long life and other industrial fields has been widely used, makes the valve sealing surface in the process of opening and closing without any extrusion, abrasion, wear and tear, so that the service life of the butterfly valve sealing and increase as the number of levels.Butterfly valves in full open, with a small flow resistance, when the opening between about 15° to 70°, and sensitive flow control, so in the field of large diameter regulation, butterfly valve is very common, and will gradually become the dominant valve type.Most butterfly valves can be used in media with suspended solids due to the wipeability of the disc movement, depending on the strength of the seal can also be used in powder and granular media.The rotary center of butterfly plate (that is, the center of valve shaft) and the sealing surface of butterfly plate form A dimension A offset, and A B offset with the center line of valve body;The center line of the body sealing surface is at an Angle to the center line of the seat (i.e. the center line of the body).

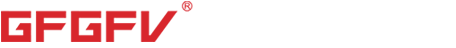

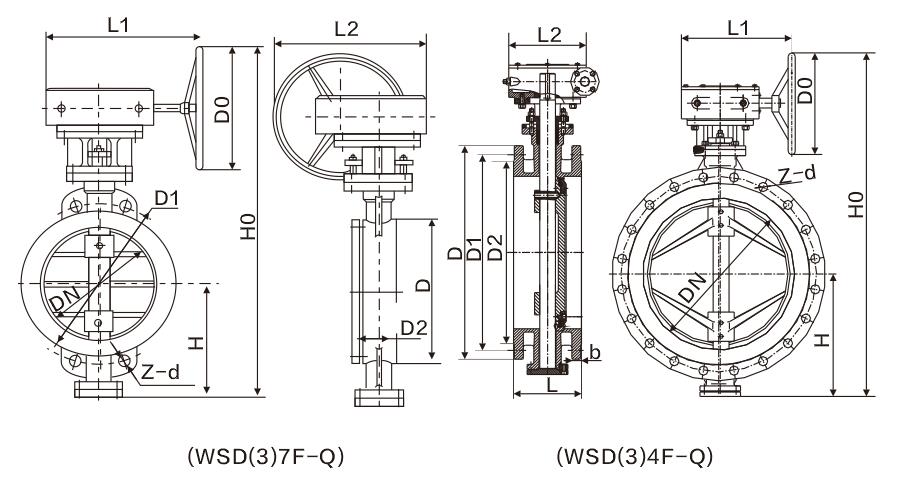

Quality assurance: ISO9000

Design: CJ/T167

Structure length: GB/T12221

Flange standard: GB/T17241.6\API 598 GB/T 9113

Test standard: GB/T13927

Nominal diameter: DN50-DN3500 NPS2 "-160"

Nominal pressure: PN0.6Mpa-PN10mpa Class125-600lb

Applicable temperature: ≤80℃

Applicable medium: gas, natural gas, gas, liquefied gas, etc

Main material: A48, A536, WCB, LCB, CF8, CF8M, CF3, CF3M, etc.

Type of construction: sandwich, welded, flange

|

DN |

Length of structure (standard value) |

External dimensions (reference value) |

Connection size (standard value) |

WSD(4)7F -Q WT(Kg) |

||||||||||||||

|

H |

WSD(4)7F -Q |

WSD(6)7F -Q |

WSD(9)7F -Q |

PN0.6MPa |

PN1.0MPa |

|||||||||||||

|

inches |

mm |

Short |

Long |

H1 |

A1 |

B1 |

H2 |

A2 |

B2 |

H3 |

A3 |

B3 |

D1 |

z-d |

D1 |

z-d |

||

|

40 |

1 1/2 |

43 |

43 |

107 |

330 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

100 |

4-14 |

110 |

4-18 |

10 |

|

50 |

2 |

43 |

43 |

112 |

350 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

110 |

4-14 |

125 |

4-18 |

12 |

|

65 |

2 1/2 |

46 |

46 |

115 |

370 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

130 |

4-14 |

145 |

4-18 |

13 |

|

80 |

3 |

49 |

64 |

125 |

380 |

180 |

200 |

645 |

245 |

72 |

565 |

250 |

255 |

150 |

4-18 |

160 |

8-18 |

15 |

|

100 |

4 |

56 |

64 |

138 |

420 |

180 |

200 |

675 |

355 |

92 |

600 |

250 |

255 |

170 |

4-18 |

180 |

8-18 |

17 |

|

125 |

5 |

64 |

70 |

164 |

460 |

180 |

200 |

715 |

355 |

92 |

640 |

250 |

255 |

200 |

8-18 |

210 |

8-18 |

27 |

|

150 |

6 |

70 |

76 |

175 |

555 |

270 |

280 |

800 |

355 |

92 |

704 |

300 |

315 |

225 |

8-18 |

240 |

8-22 |

29 |

|

200 |

8 |

71 |

89 |

215 |

780 |

400 |

425 |

850 |

250 |

170 |

775 |

300 |

315 |

280 |

8-18 |

295 |

8-22 |

45 |

|

250 |

10 |

76 |

114 |

243 |

840 |

400 |

425 |

925 |

250 |

170 |

945 |

300 |

315 |

335 |

12-18 |

350 |

12-22 |

69 |

|

300 |

12 |

83 |

114 |

285 |

995 |

450 |

560 |

1035 |

450 |

220 |

1070 |

300 |

315 |

395 |

12-22 |

400 |

12-22 |

86 |

|

350 |

14 |

92 |

127 |

320 |

1050 |

450 |

560 |

1070 |

450 |

220 |

1140 |

300 |

315 |

445 |

12-22 |

460 |

16-22 |

122 |

|

400 |

16 |

102 |

140 |

350 |

1220 |

535 |

580 |

1190 |

450 |

220 |

1210 |

300 |

315 |

495 |

16-22 |

515 |

16-26 |

141 |

|

450 |

18 |

114 |

152 |

350 |

1280 |

535 |

580 |

1250 |

650 |

280 |

1335 |

575 |

714 |

550 |

16-22 |

565 |

20-26 |

191 |

|

500 |

20 |

127 |

152 |

380 |

1365 |

535 |

580 |

1290 |

650 |

280 |

1415 |

575 |

714 |

600 |

20-22 |

620 |

20-26 |

260 |

|

600 |

24 |

154 |

178 |

435 |

1460 |

570 |

660 |

1455 |

850 |

380 |

1605 |

656 |

810 |

705 |

20-26 |

725 |

20-30 |

380 |

|

700 |

28 |

165 |

229 |

480 |

1520 |

750 |

550 |

1585 |

850 |

380 |

1844 |

656 |

810 |

810 |

24-26 |

840 |

24-30 |

450 |

|

800 |

32 |

190 |

241 |

530 |

1710 |

750 |

550 |

1700 |

1250 |

380 |

2040 |

656 |

810 |

920 |

24-30 |

950 |

24-33 |

650 |

|

900 |

36 |

203 |

241 |

595 |

1810 |

750 |

550 |

1965 |

1250 |

380 |

2255 |

785 |

863 |

1020 |

24-30 |

1050 |

28-33 |

830 |

|

1000 |

40 |

216 |

300 |

650 |

1900 |

900 |

750 |

2015 |

1250 |

380 |

2380 |

785 |

863 |

1120 |

28-30 |

1160 |

28-36 |

1050 |

|

1200 |

48 |

254 |

360 |

775 |

1180 |

1000 |

925 |

2250 |

1250 |

380 |

2640 |

785 |

863 |

1340 |

32-33 |

1380 |

32-39 |

1400 |

|

1400 |

56 |

279 |

390 |

870 |

1450 |

1000 |

925 |

|

|

|

2886 |

|

|

1560 |

36-36 |

1590 |

36-42 |

1900 |

|

1600 |

64 |

318 |

440 |

1000 |

1730 |

1000 |

925 |

|

|

|

3156 |

|

|

1760 |

40-36 |

1820 |

40-48 |

2900 |

|

1800 |

72 |

356 |

490 |

1110 |

3020 |

1100 |

980 |

|

|

|

3421 |

|

|

1970 |

44-39 |

2020 |

44-48 |

4000 |

|

2000 |

80 |

406 |

540 |

1250 |

3270 |

1100 |

980 |

|

|

|

3685 |

|

|

2180 |

48-42 |

2230 |

48-48 |

5300 |

|

DN |

|

External dimensions (reference value) | Connection size (standard value) | |||||||||||||||||||||||||||||||

|

H |

WSD(4)4F -Q |

WSD(6)4F -Q |

WSD(9)4F -Q |

PN0.25MPa |

PN0.6MPa |

PN1.0MPa |

||||||||||||||||||||||||||||

| inches |

mm |

Short |

Long |

H1 |

A1 |

B1 |

H2 |

A2 |

B2 |

H3 |

A3 |

B3 |

D |

D1 |

z-d | D | D1 |

z-d |

D |

D1 |

z-d |

|||||||||||||

|

40 |

1 1/2 |

106 | 140 | 107 | 330 | 180 | 200 | 605 | 245 | 72 | 530 | 250 | 255 | 130 |

100 |

4-14 |

130 |

100 |

4-14 |

150 |

110 |

4-18 |

||||||||||||

|

50 |

2 |

108 |

150 |

112 |

350 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

140 |

110 |

4-14 |

140 |

110 |

4-14 |

165 |

125 |

4-18 |

||||||||||||

|

65 |

2 1/2 |

112 |

170 |

115 |

370 |

180 |

200 |

645 |

245 |

72 |

530 |

250 |

255 |

160 |

130 |

4-14 |

160 |

130 |

4-14 |

185 |

145 |

4-18 |

||||||||||||

|

80 |

3 |

114 |

180 |

120 |

380 |

180 |

200 |

675 |

355 |

92 |

565 |

250 |

255 |

190 |

150 |

4-18 |

190 |

150 |

4-18 |

200 |

160 |

8-18 |

||||||||||||

|

100 |

4 |

127 |

190 |

138 |

420 |

180 |

200 |

715 |

355 |

92 |

600 |

250 |

255 |

210 |

170 |

4-18 |

210 |

170 |

4-18 |

220 |

180 |

8-18 |

||||||||||||

|

125 |

5 |

140 |

200 |

164 |

460 |

180 |

200 |

800 |

355 |

92 |

640 |

250 |

255 |

240 |

200 |

8-18 |

240 |

200 |

8-18 |

250 |

210 |

8-18 |

||||||||||||

|

150 |

6 |

140 |

210 |

175 |

555 |

270 |

280 |

850 |

250 |

170 |

705 |

300 |

315 |

265 |

225 |

8-18 |

265 |

225 |

8-18 |

285 |

240 |

8-22 |

||||||||||||

|

200 |

8 |

152 |

230 |

200 |

760 |

400 |

425 |

925 |

250 |

170 |

775 |

300 |

315 |

320 |

280 |

8-18 |

320 |

280 |

8-18 |

340 |

295 |

8-22 |

||||||||||||

|

250 |

10 |

165 |

250 |

243 |

830 |

400 |

425 |

1035 |

450 |

220 |

945 |

300 |

315 |

375 |

335 |

12-18 |

375 |

335 |

12-18 |

395 |

350 |

12-22 |

||||||||||||

|

300 |

12 |

178 |

270 |

250 |

895 |

450 |

560 |

1070 |

450 |

220 |

1070 |

300 |

315 |

440 |

395 |

12-22 |

440 |

395 |

12-22 |

445 |

400 |

12-22 |

||||||||||||

|

350 |

14 |

190 |

290 |

280 |

950 |

450 |

560 |

1190 |

450 |

280 |

1140 |

300 |

315 |

490 |

445 |

12-22 |

490 |

445 |

12-22 |

505 |

460 |

16-22 |

||||||||||||

|

400 |

16 |

216 |

310 |

305 |

1190 |

535 |

580 |

1250 |

650 |

280 |

1210 |

300 |

315 |

540 |

495 |

16-22 |

540 |

495 |

16-22 |

565 |

515 |

16-26 |

||||||||||||

|

450 |

18 |

222 |

330 |

350 |

1255 |

535 |

580 |

1295 |

650 |

280 |

1335 |

575 |

714 |

595 |

550 |

16-22 |

595 |

550 |

16-22 |

615 |

565 |

20-26 |

||||||||||||

|

500 |

20 |

229 |

350 |

380 |

1305 |

535 |

580 |

1455 |

850 |

380 |

1415 |

575 |

714 |

645 |

600 |

20-22 |

645 |

600 |

20-22 |

670 |

620 |

20-26 |

||||||||||||

|

600 |

24 |

267 |

390 |

445 |

1340 |

570 |

660 |

1585 |

850 |

380 |

1605 |

656 |

810 |

755 |

705 |

20-26 |

755 |

705 |

20-26 |

780 |

725 |

20-30 |

||||||||||||

|

700 |

28 |

292 |

430 |

480 |

1520 |

750 |

550 |

1700 |

1250 |

380 |

1844 |

656 |

810 |

860 |

810 |

24-26 |

860 |

810 |

24-26 |

895 |

840 |

24-30 |

||||||||||||

|

800 |

32 |

318 |

470 |

530 |

1710 |

750 |

550 |

1865 |

1250 |

380 |

2040 |

656 |

810 |

975 |

920 |

24-30 |

975 |

920 |

24-30 |

1015 |

950 |

24-33 |

||||||||||||

|

900 |

36 |

330 |

510 |

580 |

1810 |

750 |

550 |

2015 |

1500 |

580 |

2255 |

785 |

863 |

1075 |

1020 |

24-30 |

1075 |

1020 |

24-30 |

1115 |

1050 |

28-33 |

||||||||||||

|

1000 |

40 |

410 |

550 |

650 |

1960 |

900 |

750 |

2226 |

1500 |

580 |

2380 |

785 |

863 |

1175 |

1120 |

28-30 |

1175 |

1120 |

28-30 |

1230 |

1160 |

28-36 |

||||||||||||

|

1200 |

48 |

470 |

630 |

760 |

2250 |

1000 |

925 |

|

|

|

2640 |

785 |

863 |

1375 |

1320 |

32-30 |

1405 |

1340 |

32-33 |

1455 |

1380 |

32-39 |

||||||||||||

|

1400 |

56 |

530 |

710 |

850 |

2435 |

1000 |

925 |

|

|

|

2886 |

|

|

1575 |

1520 |

36-30 |

1630 |

1560 |

36-36 |

1675 |

1590 |

36-42 |

||||||||||||

|

1600 |

64 |

600 |

790 |

1030 |

2780 |

1000 |

925 |

|

|

|

3156 |

|

|

1790 |

1730 |

40-30 |

1830 |

1760 |

40-36 |

1915 |

1820 |

40-48 |

||||||||||||

|

1800 |

72 |

670 |

870 |

1230 |

3020 |

1100 |

980 |

|

|

|

3421 |

|

|

1990 |

1930 |

44-30 |

2045 |

1970 |

44-39 |

2115 |

2020 |

44-48 |

||||||||||||

|

2000 |

80 |

760 |

950 |

1350 |

3270 |

1100 |

980 |

|

|

|

3685 |

|

|

2190 |

2130 |

48-30 |

2265 |

2180 |

48-42 |

2325 |

2230 |

48-48 |

||||||||||||

|

DN |

L |

External dimensions (reference value) |

Flange dnwnsions (standard) |

||||||||||||||||

|

mm |

Inches |

Short |

Long |

H |

WSD(4)4F -Q |

WSD(6)4F -Q |

WSD(9)4F -Q |

PN1.6MPa |

PN2.5MPa |

||||||||||

|

H1 |

A1 |

B1 |

H2 |

A2 |

B2 |

H3 |

A3 |

B3 |

D |

D1 |

Z-d |

D |

D1 |

Z-d |

|||||

|

50 |

2 |

108 |

150 |

112 |

350 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

165 |

125 |

4-18 |

165 |

125 |

4-18 |

|

65 |

2 1/2 |

112 |

170 |

115 |

370 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

185 |

145 |

4-18 |

185 |

145 |

8-18 |

|

80 |

3 |

114 |

180 |

120 |

380 |

180 |

200 |

645 |

245 |

72 |

565 |

250 |

255 |

200 |

160 |

8-18 |

200 |

160 |

8-18 |

|

100 |

4 |

127 |

190 |

138 |

420 |

180 |

200 |

675 |

355 |

92 |

600 |

250 |

255 |

220 |

180 |

8-18 |

235 |

190 |

8-22 |

|

125 |

5 |

140 |

200 |

164 |

460 |

180 |

200 |

715 |

355 |

92 |

640 |

250 |

255 |

250 |

210 |

8-18 |

270 |

220 |

8-26 |

|

150 |

6 |

140 |

210 |

175 |

555 |

270 |

280 |

800 |

355 |

92 |

705 |

300 |

315 |

285 |

240 |

8-22 |

300 |

250 |

8-26 |

|

200 |

8 |

152 |

230 |

200 |

760 |

400 |

425 |

850 |

250 |

170 |

775 |

300 |

315 |

340 |

295 |

12-22 |

360 |

310 |

12-26 |

|

250 |

10 |

165 |

250 |

243 |

830 |

400 |

425 |

925 |

250 |

170 |

945 |

300 |

315 |

405 |

355 |

12-26 |

425 |

370 |

12-30 |

|

300 |

12 |

178 |

270 |

250 |

895 |

450 |

560 |

1035 |

450 |

220 |

1070 |

300 |

315 |

460 |

410 |

12-26 |

485 |

430 |

16-30 |

|

350 |

14 |

190 |

290 |

280 |

950 |

450 |

560 |

1070 |

450 |

220 |

1140 |

300 |

315 |

520 |

470 |

16-26 |

555 |

490 |

16-33 |

|

400 |

16 |

216 |

310 |

305 |

1190 |

535 |

580 |

1190 |

450 |

220 |

1210 |

300 |

315 |

580 |

525 |

16-30 |

620 |

550 |

16-36 |

|

450 |

18 |

222 |

330 |

350 |

1255 |

535 |

580 |

1250 |

650 |

280 |

1335 |

575 |

714 |

640 |

585 |

20-30 |

670 |

600 |

20-36 |

|

500 |

20 |

229 |

350 |

380 |

1305 |

535 |

580 |

1290 |

650 |

280 |

1415 |

575 |

714 |

715 |

650 |

20-33 |

730 |

660 |

20-36 |

|

600 |

24 |

267 |

390 |

445 |

1340 |

570 |

660 |

1455 |

850 |

380 |

1605 |

656 |

810 |

840 |

770 |

20-36 |

845 |

770 |

20-39 |

|

700 |

28 |

292 |

430 |

480 |

1520 |

750 |

550 |

1585 |

850 |

380 |

1844 |

656 |

810 |

910 |

840 |

24-36 |

960 |

875 |

24-42 |

|

800 |

32 |

318 |

470 |

530 |

1710 |

750 |

550 |

1700 |

1250 |

380 |

2040 |

656 |

810 |

1025 |

950 |

24-39 |

1085 |

990 |

24-48 |

|

900 |

36 |

330 |

510 |

580 |

1810 |

750 |

550 |

1865 |

1250 |

380 |

2255 |

785 |

863 |

1125 |

1050 |

28-39 |

1185 |

1090 |

28-48 |

|

1000 |

40 |

410 |

550 |

650 |

1960 |

900 |

750 |

2015 |

1250 |

380 |

2380 |

785 |

863 |

1255 |

1170 |

28-42 |

1320 |

1210 |

28-56 |

|

1200 |

48 |

470 |

630 |

760 |

2250 |

1000 |

925 |

2250 |

1250 |

380 |

2640 |

785 |

863 |

1485 |

1390 |

32-48 |

1530 |

1420 |

32-56 |

|

1400 |

56 |

530 |

710 |

850 |

2435 |

1000 |

925 |

|

|

|

2886 |

|

|

1685 |

1590 |

36-48 |

1755 |

1640 |

36-62 |

|

1600 |

64 |

600 |

790 |

1030 |

2780 |

1000 |

925 |

|

|

|

3156 |

|

|

1930 |

1820 |

40-56 |

1975 |

1860 |

40-62 |

|

1800 |

72 |

670 |

870 |

1230 |

3020 |

1100 |

980 |

|

|

|

3421 |

|

|

2130 |

2020 |

44-56 |

2195 |

2070 |

44-70 |

|

2000 |

80 |

760 |

950 |

1350 |

3270 |

1100 |

980 |

|

|

|

3685 |

|

|

2345 |

2230 |

48-62 |

2425 |

2300 |

48-70 |

| DN | Structure length L | External dimensions (reference value) | Flange dnwnsions (standard) | |||||||||||||

| mm | Inches | L | H | WSD(4)4F -Q | WSD(6)4F -Q | WSD(9)4F -Q | PN4.0MPa | |||||||||

| Short | Long | H1 | A1 | B1 | H2 | A2 | B2 | H3 | A3 | B3 | D | D1 | Z-d | |||

| 50 | 2 | 108 | 150 | 112 | 350 | 180 | 200 | 625 | 250 | 170 | 530 | 250 | 255 | 165 | 125 | 4-18 |

| 65 | 2 1/2 | 112 | 170 | 115 | 370 | 270 | 280 | 625 | 250 | 170 | 530 | 250 | 255 | 185 | 145 | 8-18 |

| 80 | 3 | 114 | 180 | 120 | 380 | 270 | 280 | 645 | 250 | 170 | 565 | 250 | 255 | 200 | 160 | 8-18 |

| 100 | 4 | 127 | 190 | 138 | 420 | 270 | 280 | 675 | 250 | 170 | 600 | 250 | 255 | 235 | 190 | 8-22 |

| 125 | 5 | 140 | 200 | 164 | 460 | 380 | 420 | 715 | 450 | 220 | 640 | 250 | 255 | 270 | 220 | 8-26 |

| 150 | 6 | 140 | 210 | 175 | 555 | 380 | 420 | 800 | 450 | 220 | 704 | 300 | 315 | 300 | 250 | 8-26 |

| 200 | 8 | 152 | 230 | 208 | 780 | 400 | 425 | 850 | 450 | 220 | 775 | 300 | 315 | 375 | 320 | 12-30 |

| 250 | 10 | 165 | 250 | 243 | 830 | 400 | 425 | 925 | 450 | 280 | 945 | 300 | 315 | 450 | 385 | 12-33 |

| 300 | 12 | 178 | 270 | 285 | 895 | 450 | 560 | 1035 | 650 | 280 | 1070 | 300 | 315 | 515 | 450 | 16-33 |

| 350 | 14 | 190 | 290 | 320 | 950 | 450 | 560 | 1070 | 650 | 280 | 1140 | 300 | 315 | 580 | 510 | 16-36 |

| 400 | 16 | 216 | 310 | 350 | 1190 | 535 | 580 | 1190 | 650 | 280 | 1210 | 300 | 315 | 660 | 585 | 16-39 |

| 450 | 18 | 222 | 330 | 350 | 1255 | 535 | 580 | - | - | - | 1335 | 575 | 714 | 685 | 610 | 20-39 |

| 500 | 20 | 229 | 350 | 380 | 1305 | 535 | 580 | - | - | - | 1415 | 575 | 714 | 755 | 670 | 20-42 |

Privacy policy

2. We will adopt technical and management measures to protect users' privacy.When sensitive information is provided to us by users, we will take reasonable steps to protect sensitive information of users, and we will also take reasonable security measures to protect personal information that has been stored.This website will strictly manage and protect the data provided by users, and will use the corresponding technology to prevent the loss, theft or change of users' personal data.

3. The website of China National Engineering Holding Group Co., Ltd. will strictly protect users' personal privacy and promise not to arbitrarily disclose users' personal information without users' consent.However, under the following exceptions, the aforementioned promises will not be warranted to disclose the user's relevant information.These circumstances include, but are not limited to: (1) when the user behavior on this site violates the measures for the administration of international networking of computer information network security protection, the measures for the administration of Internet information service, the "Internet electronic bulletin service management regulations" and "the standing committee of the National People's Congress on maintaining Internet security decision", or may damage or interfere with the rights and interests of other users or cause others to suffer damage, disclosure of personal information is to identify the user, contact, or to take legal action when necessary action.

(2) Personal information that must be disclosed or made public as required by laws and regulations.

(3) When judicial organs or other authorized organs perform official duties according to law and require websites to disclose specific personal data.

4. The website of China National Engineering Holding Group Co., Ltd. has taken complete technical measures to protect the integrity and confidentiality of users' information.However, the website of China National Industry Holding Group Co., Ltd. shall not bear any legal liability for the damage, disclosure and loss of user information caused by force majeure or special external forces such as computer virus infection or hacker attack, but we will take necessary measures to reduce the loss of users.

5. At any time when users think that the website of China National Industry Holding Group Co., Ltd. does not comply with this statement, please inform us by E-mail to GuoGong@GFGFV.com and we will make every effort to take corresponding improvement measures.

Legal notices

Second, all pages in the official website of creative format framework, animation, interactive design, structure, color, text, ICONS and other appropriate combination, in the form of digital published in digital form and fixed on the computer's hard drive space, contact by the public with the help of a network host, give a person with visual aesthetic feeling, this is not a simple arrangement of facts, has the originality.The above description is protected by this copyright notice.

Iii. We have tried our best to obtain permission from the copyright owner for the information reproduced on this website. If there is any omission, please contact this website.

Iv. The views expressed or implied in the relevant articles and materials reproduced on this website do not represent that of China National Industry Holding Group Co., LTD.

V. This website cannot control or guarantee the accuracy, timeliness and completeness of the information of each website linked to it.

The right to modify and update the website Statement belongs to the website of China National Industry Holding Group Co., LTD.