1、为防止中腔异常升压,在闸板的进口侧设置了泄压孔;

2、根据阀门的工作温度确定阀盖的顶部长度,确保阀杆填料的可靠密封;

3、根据工作温度合理选用填料,垫片等零件的材料;

4、严格控制材料的化学成份及低温冲击韧性等力学性能指标;

5、采用多种配管法兰标准及密封面型式,适用于各种工程需要。

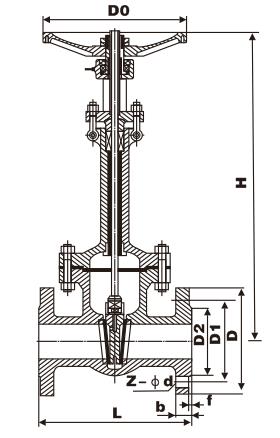

设计规范:JB/T7749

结构长度:GB/T12221

连接法兰:JB/T79.1、HG/T20592、GB/T9113

试验与检验:JB/T9092、GB/T13927

压力-温度:GB/T12224

公称通径:DN20~400mm

公称压力:PN1.6~10MPa

适用温度:-45℃~196℃

主要材质:C3、LCB、LCC、1Cr18Ni9Ti

适用介质:甲烷、液态天然气、乙烯、二氧化碳、液氨、液氧、液氟、液氢等低温介质

|

DN(mm)

|

L |

D |

Di |

D2 |

b |

Z-Φd |

H |

Do |

WT(kg) |

|

|

DZ40Y-16P/R/PL/RL |

DZ640Y-16P/R/PL/RL |

DZ940Y-16P/R/PURL |

|

|

||||

|

20 |

150 |

105 |

75 |

55 |

14 |

4-Φ14 |

320 |

140 |

6 |

|

25 |

160 |

115 |

85 |

65 |

14 |

4-Φ14 |

350 |

160 |

7 |

|

32 |

180 |

135 |

100 |

78 |

16 |

4-Φ18 |

385 |

180 |

9 |

|

40 |

200 |

145 |

110 |

85 |

16 |

4-Φ18 |

420 |

200 |

15 |

|

50 |

250 |

160 |

125 |

100 |

16 |

4-Φ18 |

540 |

240 |

30 |

|

65 |

265 |

180 |

145 |

120 |

18 |

4-Φ18 |

610 |

240 |

34 |

|

80 |

280 |

195 |

160 |

135 |

20 |

8-Φ18 |

690 |

280 |

45 |

|

100 |

300 |

215 |

180 |

155 |

20 |

8-Φ18 |

780 |

300 |

64 |

|

125 |

325 |

245 |

210 |

185 |

22 |

8-Φ18 |

930 |

320 |

110 |

|

150 |

350 |

280 |

240 |

210 |

24 |

8-Φ23 |

980 |

360 |

135 |

|

200 |

400 |

335 |

295 |

265 |

26 |

12-Φ23 |

1180 |

400 |

195 |

|

250 |

450 |

405 |

355 |

320 |

30 |

12-Φ25 |

1390 |

450 |

275 |

|

300 |

500 |

460 |

410 |

375 |

30 |

12-Φ25 |

1620 |

560 |

380 |

|

350 |

550 |

520 |

470 |

435 |

34 |

16-Φ25 |

1810 |

640 |

594 |

|

400 |

600 |

580 |

525 |

485 |

36 |

16-Φ30 |

1970 |

640 |

725 |

|

DZ40Y-25P/R/PL/RL DZ640Y-25P/R/PL/RL DZ940Y-25P/R/PL/RL |

|||||||||

|

20 |

150 |

105 |

75 |

55 |

16 |

4-Φ14 |

320 |

140 |

6 |

|

25 |

160 |

115 |

85 |

65 |

16 |

4-Φ14 |

350 |

160 |

8 |

|

32 |

180 |

136 |

100 |

78 |

18 |

4-Φ18 |

385 |

180 |

10 |

|

40 |

200 |

145 |

110 |

85 |

18 |

4-Φ18 |

420 |

200 |

16 |

|

50 |

250 |

160 |

125 |

100 |

20 |

4-Φ18 |

540 |

240 |

30 |

|

65 |

265 |

180 |

145 |

120 |

22 |

4-Φ18 |

610 |

240 |

35 |

|

80 |

280 |

195 |

160 |

135 |

22 |

8-Φ18 |

690 |

280 |

47 |

|

100 |

300 |

230 |

190 |

160 |

24 |

8-Φ23 |

780 |

300 |

65 |

|

125 |

|

270 |

220 |

188 |

28 |

8-Φ25 |

930 |

320 |

110 |

|

150 |

350 |

300 |

250 |

218 |

30 |

8-Φ25 |

980 |

360 |

135 |

|

200 |

400 |

360 |

310 |

278 |

34 |

12-Φ25 |

1180 |

400 |

215 |

|

250 |

450 |

425 |

370 |

332 |

36 |

12-Φ30 |

1390 |

450 |

295 |

|

300 |

500 |

485 |

430 |

390 |

40 |

16-Φ30 |

1620 |

560 |

400 |

|

350 |

550 |

550 |

490 |

448 |

44 |

16-Φ34 |

1810 |

640 |

630 |

|

400 |

600 |

610 |

550 |

505 |

48 |

16-Φ34 |

1990 |

640 |

910 |

|

DN(mm) |

L |

D |

D1 |

D2 |

D6 |

b |

Z-Φd |

H |

Do |

WT(kg) |

|

|

|

|

|

DZ40Y-40P/R/PL/RL |

|

|

|

|

||

|

20 |

150 |

105 |

75 |

55 |

51 |

16 |

4-Φ14 |

330 |

140 |

7 |

|

25 |

160 |

115 |

85 |

65 |

58 |

16 |

4-Φ14 |

360 |

160 |

9 |

|

32 |

180 |

135 |

100 |

78 |

66 |

18 |

4-Φ18 |

440 |

180 |

11 |

|

40 |

200 |

145 |

110 |

85 |

76 |

18 |

4-Φ18 |

455 |

200 |

19 |

|

50 |

250 |

160 |

125 |

100 |

88 |

20 |

4-Φ18 |

575 |

280 |

28 |

|

65 |

280 |

180 |

145 |

120 |

110 |

22 |

8-Φ18 |

635 |

280 |

35 |

|

80 |

310 |

195 |

160 |

135 |

121 |

22 |

8-Φ18 |

715 |

320 |

50 |

|

100 |

350 |

230 |

190 |

160 |

150 |

24 |

8-Φ23 |

815 |

360 |

74 |

|

125 |

400 |

270 |

220 |

188 |

176 |

28 |

8-Φ25 |

965 |

400 |

115 |

|

150 |

450 |

300 |

250 |

218 |

204 |

30 |

8-Φ25 |

1025 |

400 |

135 |

|

200 |

550 |

375 |

320 |

282 |

260 |

38 |

12-Φ30 |

1225 |

450 |

215 |

|

250 |

650 |

445 |

385 |

345 |

313 |

42 |

12-Φ34 |

1440 |

560 |

184 |

|

300 |

750 |

510 |

450 |

408 |

364 |

46 |

16-Φ34 |

1665 |

640 |

405 |

|

350 |

850 |

570 |

510 |

465 |

422 |

52 |

16-Φ34 |

1880 |

640 |

600 |

|

400 |

950 |

655 |

585 |

535 |

474 |

58 |

16-Φ41 |

2050 |

720 |

750 |

|

DZ40Y-64P/R/PL/RL |

||||||||||

|

20 |

190 |

125 |

90 |

68 |

51 |

20 |

4-Φ18 |

330 |

100 |

8 |

|

25 |

210 |

135 |

100 |

78 |

58 |

22 |

4-Φ18 |

360 |

180 |

13 |

|

32 |

230 |

150 |

110 |

82 |

66 |

24 |

4-Φ23 |

410 |

180 |

24 |

|

40 |

240 |

165 |

125 |

95 |

76 |

24 |

4-Φ23 |

480 |

200 |

32 |

|

50 |

250 |

175 |

135 |

105 |

88 |

26 |

4-Φ23 |

585 |

200 |

39 |

|

65 |

280 |

200 |

160 |

160 |

110 |

28 |

8-Φ30 |

690 |

250 |

45 |

|

80 |

310 |

210 |

170 |

140 |

121 |

30 |

8-Φ23 |

745 |

300 |

60 |

|

100 |

350 |

250 |

200 |

168 |

150 |

32 |

8-Φ25 |

885 |

300 |

90 |

|

125 |

400 |

295 |

240 |

202 |

176 |

36 |

8-Φ30 |

985 |

350 |

140 |

|

150 |

450 |

340 |

280 |

240 |

204 |

38 |

8-Φ34 |

1050 |

350 |

205 |

|

200 |

550 |

405 |

345 |

300 |

260 |

44 |

12-Φ34 |

1240 |

400 |

330 |

|

250 |

650 |

470 |

400 |

352 |

313 |

48 |

12-Φ41 |

1460 |

560 |

468 |

|

300 |

750 |

530 |

460 |

412 |

364 |

54 |

16-Φ41 |

1690 |

640 |

600 |

|

DZ40Y-100P/R/PL/RL |

||||||||||

|

25 |

210 |

135 |

100 |

78 |

58 |

24 |

4-Φ18 |

365 |

200 |

18 |

|

32 |

230 |

150 |

110 |

82 |

66 |

24 |

4-Φ23 |

420 |

240 |

27 |

|

50 |

250 |

195 |

145 |

112 |

88 |

28 |

4-Φ25 |

630 |

360 |

45 |

|

65 |

280 |

220 |

170 |

138 |

100 |

32 |

8-Φ25 |

700 |

400 |

60 |

|

80 |

310 |

230 |

180 |

148 |

121 |

34 |

8-Φ25 |

760 |

400 |

76 |

|

100 |

350 |

265 |

210 |

172 |

150 |

38 |

8-Φ23 |

900 |

400 |

128 |

隐私政策

1、用户使用国工控股集团有限公司网站的留言与咨询、互动提问等服务需要提供必要的个人资料,通常包括:姓名、性别、联系电话和电子邮箱。我们将对用户信息和有关需求内容进行保密管理。

2、我们将采取技术和管理手段保护用户的隐私。用户提供给我们敏感信息时,我们将采取合理的步骤保护用户的敏感信息,我们也将采取合理的安全手段保护已存储的个人信息。本网站将对用户所提供的资料进行严格的管理及保护,将使用相应的技术,防止用户的个人资料丢失、被盗用或遭改变。

3、国工控股集团有限公司网站将严格保守用户的个人隐私,承诺未在用户同意的情况下不将用户的个人信息任意披露。但是,在以下几个例外情形下,将无法保证前述的承诺,而披露用户的相关信息。这些情形包括但不限于: (1)当用户在本网站的行为违反了《计算机信息网络国际联网安全保护管理办法》、《互联网信息服务管理办法》、《互联网电子公告服务管理规定》以及《全国人大常委会关于维护互联网安全的决定》,或可能损害或妨碍其他网友的权益或导致他人遭受损害,披露用户的个人资料是为了辨识、联络或采取法律行动所必要的行动时。

(2)法律法规所规定的必须披露或公开的个人信息。

(3)当司法机关或其它授权机关依法执行公务,要求网站公开特定个人资料时。

4、国工控股集团有限公司网站采取了完备的技术措施保护用户的信息的完整性和秘密性。但由于不可抗力或者因计算机病毒感染、黑客攻击等特殊外力侵扰,导致用户信息破坏、泄密并受到损失的,国工控股集团有限公司网站不承担任何法律责任,但我们将采取必要措施尽力减少用户的损失。

5、任何时候如果用户认为国工控股集团有限公司网站没有遵守本声明时,请发送电子邮件到GuoGong@GFGFV.com 通知我们,我们会尽一切努力,采取相应的改进措施。

法律声明

二、本官方网站中所有页面的版式创意设计、结构框架、动画交互、颜色、文字、图标等以数字化的方式加以特定的组合,以数字化形式发表并固定在计算机硬盘空间上,为社会公众借助联网主机所接触,给人以视觉上的美感,此不属于简单的对事实的排列,具有独创性。以上内容描述均受本版权声明保护。

三、本网站转载的信息,已尽力取得版权人的使用许可,如有遗漏,请与本网站联系。

四、本网站转载的相关文章、资料中表述或暗示的观点不代表国工控股集团有限公司。

五、本网站不能控制或保证与之相链接的各个网站信息的准确性、及时性和完整性。

本网站《网站声明》的修改及更新权均属于国工控股集团有限公司网站。