- ABOUT

- ENVIRONMENT

-

PRODUCTS

- Heating industry

- Water conservancy industry

- Coal mine gas industry

- Coal coking industry

- Coal washing and mineral processing industry

- Chemical industry

- Petroleum and petrochemical industry

- Natural gas industry

- Electric power application industry

- Urban construction industry

- Water supply and drainage fire protection industry

- Steel smelting industry

- Food and pharmaceutical industry

- Environmental Application industry

- NEWS

- APPLICATION

- SERVICE

- CONTACT US

- Vacuum butterfly valve

- Vacuum gate valve

- Power station gate valve

- Station check valve

- Power station globe valve

- Diaphragm valve

- Accumulative fluid controlled slow closing check butterfly valve

- Extraction check valve

- Globe valve

- Check valve

- Ball valve

- All metal sealed bidirectional pressure butterfly valve

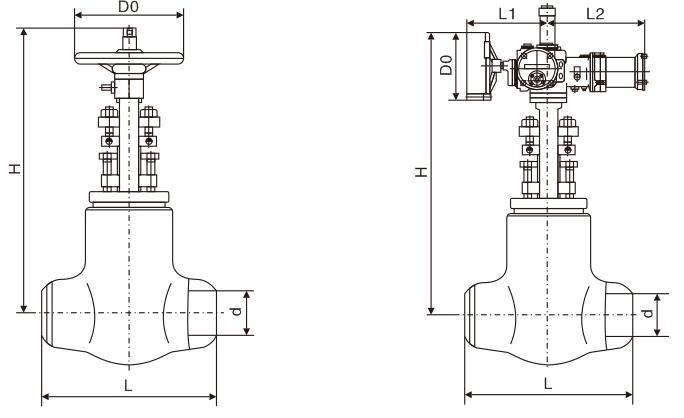

Power station gate valve

Power station gate valve is suitable for cutting off or connecting medium on pipelines of petroleum, chemical and thermal power plants with class 1500 ~ 3500lb and working temperature of - 29 ~ 570 ℃.

1. The gate valve of high temperature and high pressure class power station adopts advanced equal diameter straight through structure, which greatly reduces the flow resistance coefficient and energy loss, and significantly improves the service life and performance of the valve;

2. The middle chamber of the valve adopts pressure self tightening sealing structure with good sealing performance. Both ends of the branch pipe are welded structure;

3. The sealing surface of the gate and valve seat is made of Stellite cobalt base hardfacing, which has good wear resistance, high temperature resistance, corrosion resistance and scratch resistance;

4. After quenching and tempering and surface nitriding treatment, the valve stem has good corrosion resistance and scratch resistance;

5. The structure of the hoist can be designed as single plate, double plate and parallel double plate according to the user's requirements;

6. The opening and closing of electric gate valve is controlled by electric device, which is equipped with special motor, reducer, torque control mechanism, field operation mechanism, manual and electric switching mechanism. In addition to local operation, it can also be operated remotely.

Design specification: JB/T 3595

Structure length: JB/T 2766, GB/T 15188.1, E101

Welding groove: JB/T 3595, GB/T12224

Test and inspection: JB/T 3595 E101

Pressure-temperature: JB/T 3595

Pressure grade: Class1500 ~ 3500Lb

Suitable medium: water, steam

Applicable temperature: ≤590℃

Main materials: WCB,WC1,WC6,WC9

|

NPS (in) |

d |

L |

H |

D0 |

L1 |

L2 |

Electric dewice |

WT (Kg) |

|

Z960Y-1500Lb |

||||||||

|

21/2 |

62 |

254 |

520 |

200 |

140 |

243 |

SMC-04 |

93 |

|

3 |

74 |

305 |

523 |

508 |

140 |

243 |

SMC-04 |

110 |

|

4 |

100 |

406 |

599 599 |

508 305 |

198 400 |

281 555 |

SMC-03 SMC-00 |

168 208 |

|

5 |

103 |

483 |

678 678 |

508 305 |

198 400 |

565 654 |

SMC-03 SMC-00 |

189 232 |

|

6 |

144 |

559 |

793 793 |

305 305 |

410 420 |

565 654 |

SMC-0 SMC-1 |

358 444 |

|

8 |

192 |

711 |

813 813 |

305 305 |

410 420 |

668 654 |

SMC-0 SMC-1 |

517 561 |

|

10 |

239 |

864 |

998 998 |

457 305 |

440 420 |

654 688 |

SMC-2 SMC-1 |

852 823 |

|

12 |

287 |

991 |

1141 1156 |

305 457 |

420 440 |

SMC-1 SMC-2 |

1122 1150 |

|

|

14 |

315 |

1067 |

1249 |

610 |

690 |

SMC-3 |

1760 |

|

|

16 |

360 |

1194 |

1351 |

610 |

690 |

SMC-3 |

2429 |

|

|

18 |

406 |

1346 |

1535 1540 |

610 610 |

690 715 |

SMC-3 SMC-4 |

2454 2524 |

|

|

Z960Y-2000Lb |

||||||||

|

21/2 |

50 |

330 |

540 |

200 |

140 |

243 |

SMC-04 |

202 |

|

3 |

60 |

368 |

558 |

508 |

198 |

332 |

SMC-03 |

149 |

|

4 |

80 |

457 |

654 |

305 |

400 |

555 |

SMC-00 |

245 |

|

5 |

96 |

533 |

780 780 |

305 305 |

400 410 |

555 565 |

SMC-0 SMC-0 |

323 280 |

|

6 |

118 |

610 |

830 |

305 |

410 |

565 |

SMC-0 |

419 |

|

8 |

148 |

762 |

960 960 |

305 305 |

410 420 |

565 654 |

SMC-0 SMC-1 |

626 715 |

|

10 |

180 |

914 |

1020 1024 |

305 457 |

420 440 |

654 688 |

SMC-1 SMC-2 |

1020 1050 |

|

12 |

222 |

1041 |

1150 1166 |

457 610 |

440 690 |

688 |

SMC-2 SMC-3 |

1320 1358 |

|

14 |

254 |

1118 |

1230 1240 |

457 610 |

440 690 |

688 |

SMC-2 SMC-3 |

1810 1840 |

|

16 |

294 |

1245 |

1330 1350 |

610 610 |

690 715 |

SMC-3 SMC-4 |

2270 2300 |

|

Privacy policy

2. We will adopt technical and management measures to protect users' privacy.When sensitive information is provided to us by users, we will take reasonable steps to protect sensitive information of users, and we will also take reasonable security measures to protect personal information that has been stored.This website will strictly manage and protect the data provided by users, and will use the corresponding technology to prevent the loss, theft or change of users' personal data.

3. The website of China National Engineering Holding Group Co., Ltd. will strictly protect users' personal privacy and promise not to arbitrarily disclose users' personal information without users' consent.However, under the following exceptions, the aforementioned promises will not be warranted to disclose the user's relevant information.These circumstances include, but are not limited to: (1) when the user behavior on this site violates the measures for the administration of international networking of computer information network security protection, the measures for the administration of Internet information service, the "Internet electronic bulletin service management regulations" and "the standing committee of the National People's Congress on maintaining Internet security decision", or may damage or interfere with the rights and interests of other users or cause others to suffer damage, disclosure of personal information is to identify the user, contact, or to take legal action when necessary action.

(2) Personal information that must be disclosed or made public as required by laws and regulations.

(3) When judicial organs or other authorized organs perform official duties according to law and require websites to disclose specific personal data.

4. The website of China National Engineering Holding Group Co., Ltd. has taken complete technical measures to protect the integrity and confidentiality of users' information.However, the website of China National Industry Holding Group Co., Ltd. shall not bear any legal liability for the damage, disclosure and loss of user information caused by force majeure or special external forces such as computer virus infection or hacker attack, but we will take necessary measures to reduce the loss of users.

5. At any time when users think that the website of China National Industry Holding Group Co., Ltd. does not comply with this statement, please inform us by E-mail to GuoGong@GFGFV.com and we will make every effort to take corresponding improvement measures.

Legal notices

Second, all pages in the official website of creative format framework, animation, interactive design, structure, color, text, ICONS and other appropriate combination, in the form of digital published in digital form and fixed on the computer's hard drive space, contact by the public with the help of a network host, give a person with visual aesthetic feeling, this is not a simple arrangement of facts, has the originality.The above description is protected by this copyright notice.

Iii. We have tried our best to obtain permission from the copyright owner for the information reproduced on this website. If there is any omission, please contact this website.

Iv. The views expressed or implied in the relevant articles and materials reproduced on this website do not represent that of China National Industry Holding Group Co., LTD.

V. This website cannot control or guarantee the accuracy, timeliness and completeness of the information of each website linked to it.

The right to modify and update the website Statement belongs to the website of China National Industry Holding Group Co., LTD.